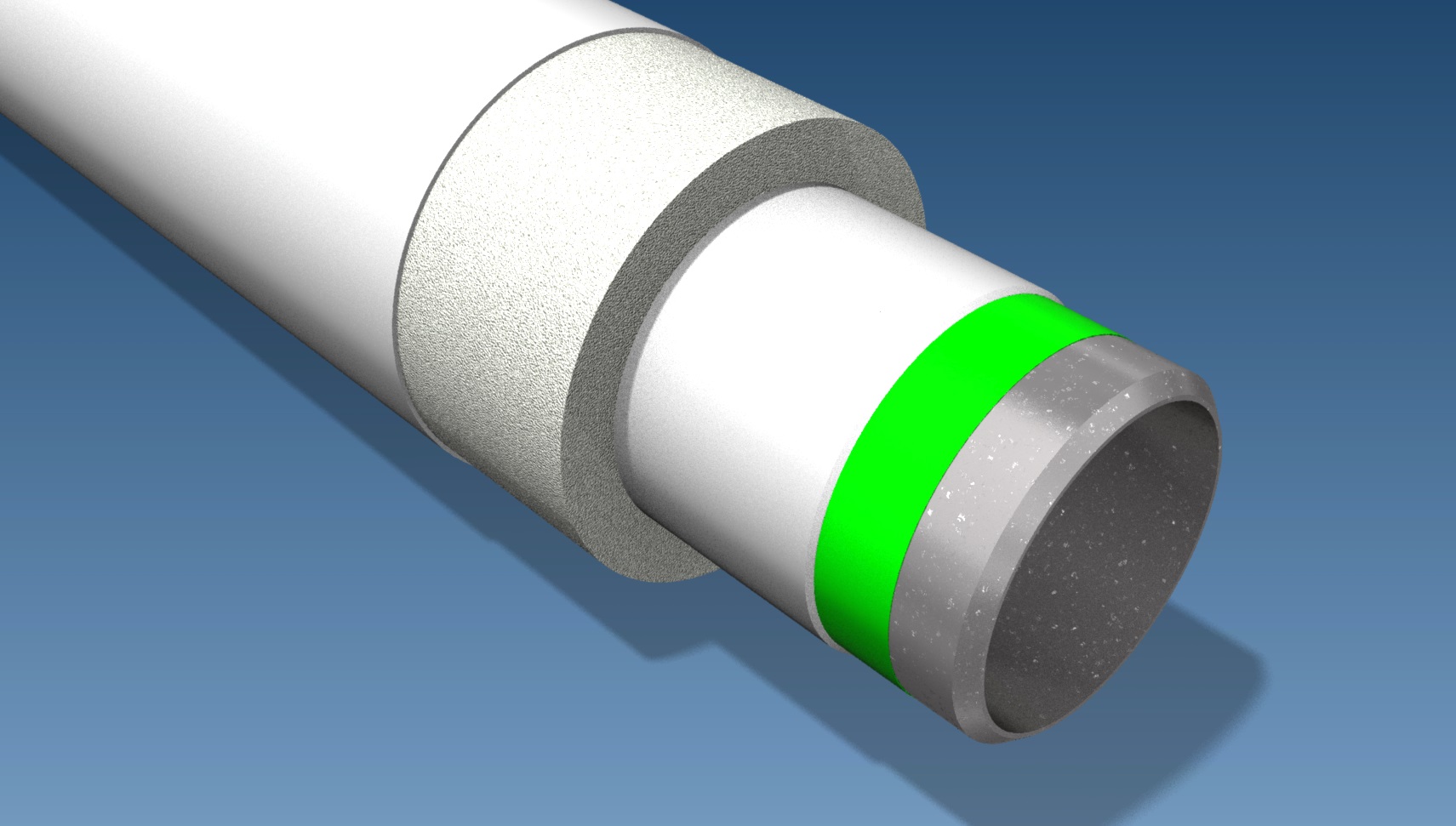

Multi-Layer Polypropylene Flow Assurance Coating

Polypropylene insulation systems are used for the thermal management of flowlines for offshore applications. Insulation can take the form of solid, foamed or syntactic polypropylene, as well as multi-layer combinations of these three materials designed specifically for each project.

Applications and Standards

The products are applied by a side extrusion process. Various layers are employed to achieve the desired thermal and buoyancy requirements. Materials are applied in accordance with project specific requirements.

SURF 9035™

SURF 9035™ material, a fully compounded polypropylene based resin, is ideal for the production of syntactic polypropylene systems for thermal management of flowlines for offshore applications. The material is designed to perform at high service temperatures specifically in deep water. Its matrix is a base polymer designed by Basell and final formulation is performed by Wasco Coatings Group insulation technology.

Features

- Excellent processability

- Good impact strength

- Excellent softness

- Low permeability to water vapor

Typical Processing Conditions

Melt temperature range: 180 °C – 220 °C

Applications: Thermal insulation pipe coating for deep water

Thermal conductivity: 0.14 to 0.18 W/m·K

U value range: 2 W/m 2·K and higher

Water depth range: 0 to 3000 m (9840 ft)

Minimum pipe diameter: 80 mm (3 in)

Maximum pipe diameter: 600 mm (24 in)

Minimum pipe length: 9 m (30 ft)

Maximum pipe length (double joint): 24 m (80 ft)

Minimum operating temperature: -20 °C (-4 °F)

Maximum operating temperature: 145 °C (293 °F)