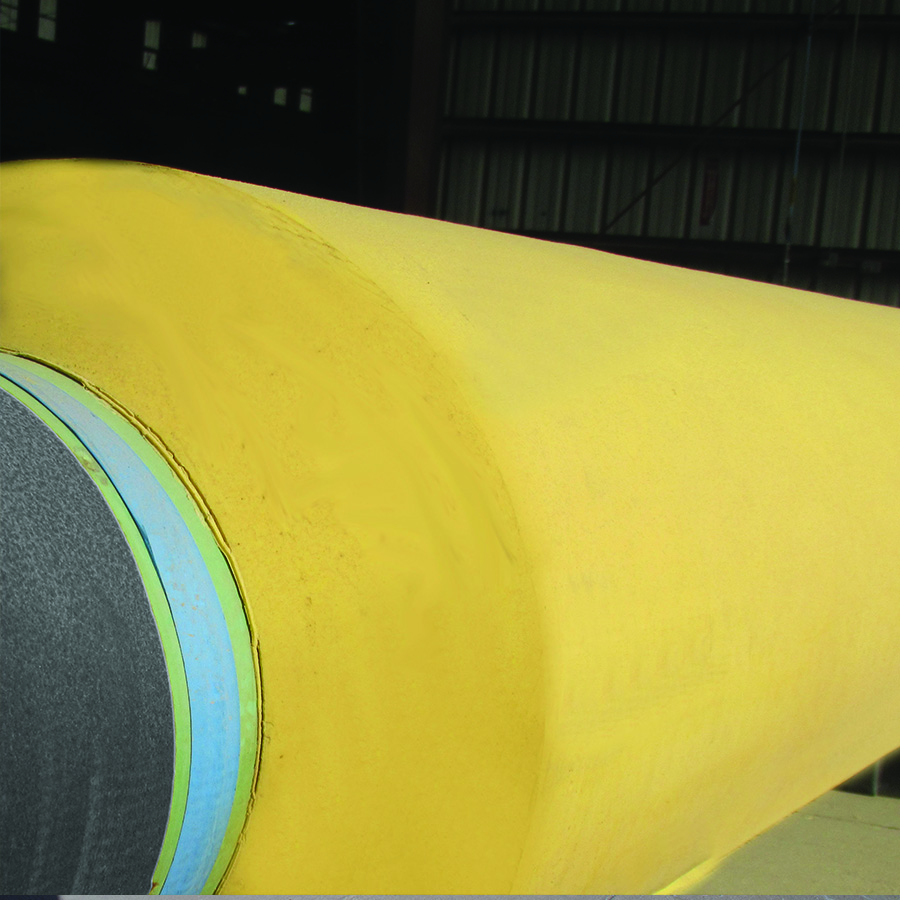

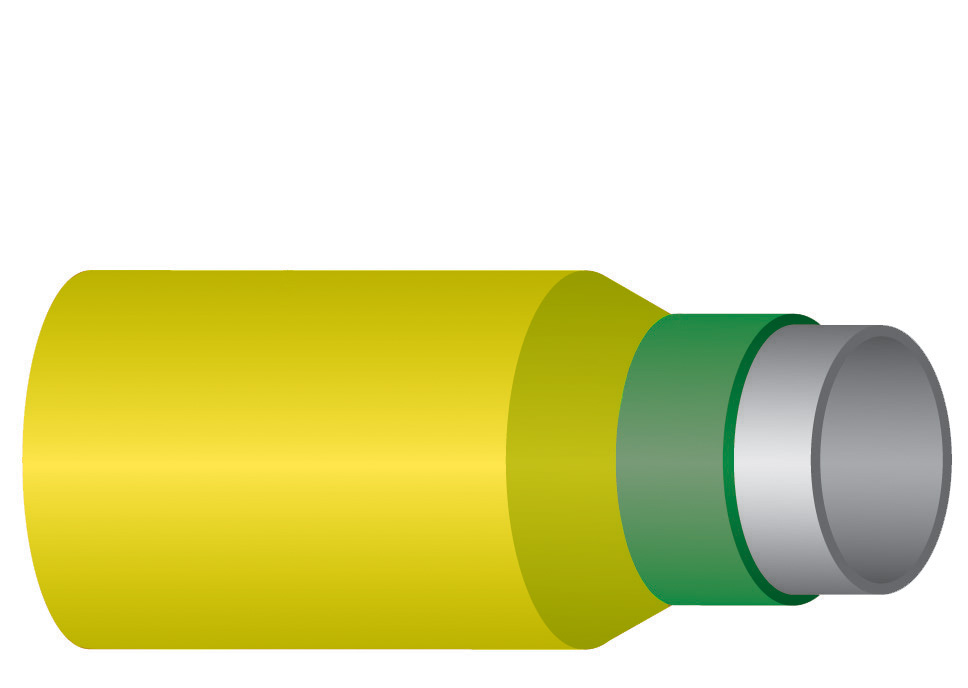

Glass Syntactic Polyurethane (GSPU)

Glass Syntactic Polyurethane (GSPU) is a flow assurance insulation system for deepwater applications used for thermal management of subsea flowlines. The product is designed to perform at high-service temperatures and is an economical alternative to 5LPP.

About the Product

- GSPU is a reaction injection molding (RIM) product. System components are blended and injected into steel molds that surround the pipe’s outer surface.

- The product contains hollow glass microspheres (HGMS) to improve resistance to heat flow and are resistant to extreme crushing forces found at subsea water depths.

- GSPU is formulated to resist chemical breakdown in hot and wet service conditions that are typically found in subsea environments.

- GSPU delivers excellent thermal insulation, adhesion, impact strength and durability across a broad spectrum of demanding installation and operating conditions.

Bayou Wasco Facilitiy

- Modern and fully automated with minimal touch points between man and machine.

- Boasts a high speed insulation process that can produce three to five joints per hour.

- The plant’s advanced features allow for more precise control of pipe and mold temperatures, more accurate centering of pipe within the insulation, greater end-centering for improved field jointing, and 100% abrasion of FBE for superior adhesion.

primary specifications

- 3 in. min to 24 in. max OD

- Pipe lengths: 35 ft. min to 42 ft. max

- Thermal conductivity: 0.1-0.17 W/mK

- U-value range: 1.5 W/m2K and higher

- Min operating temp: -35°C

- Max operating temp: 100°C

- Water depth range: 0-3,000 m

applications

-

- Deepwater locations

- Subsea, high temperature environments

MEDIA & LITERATURE

Coming Soon