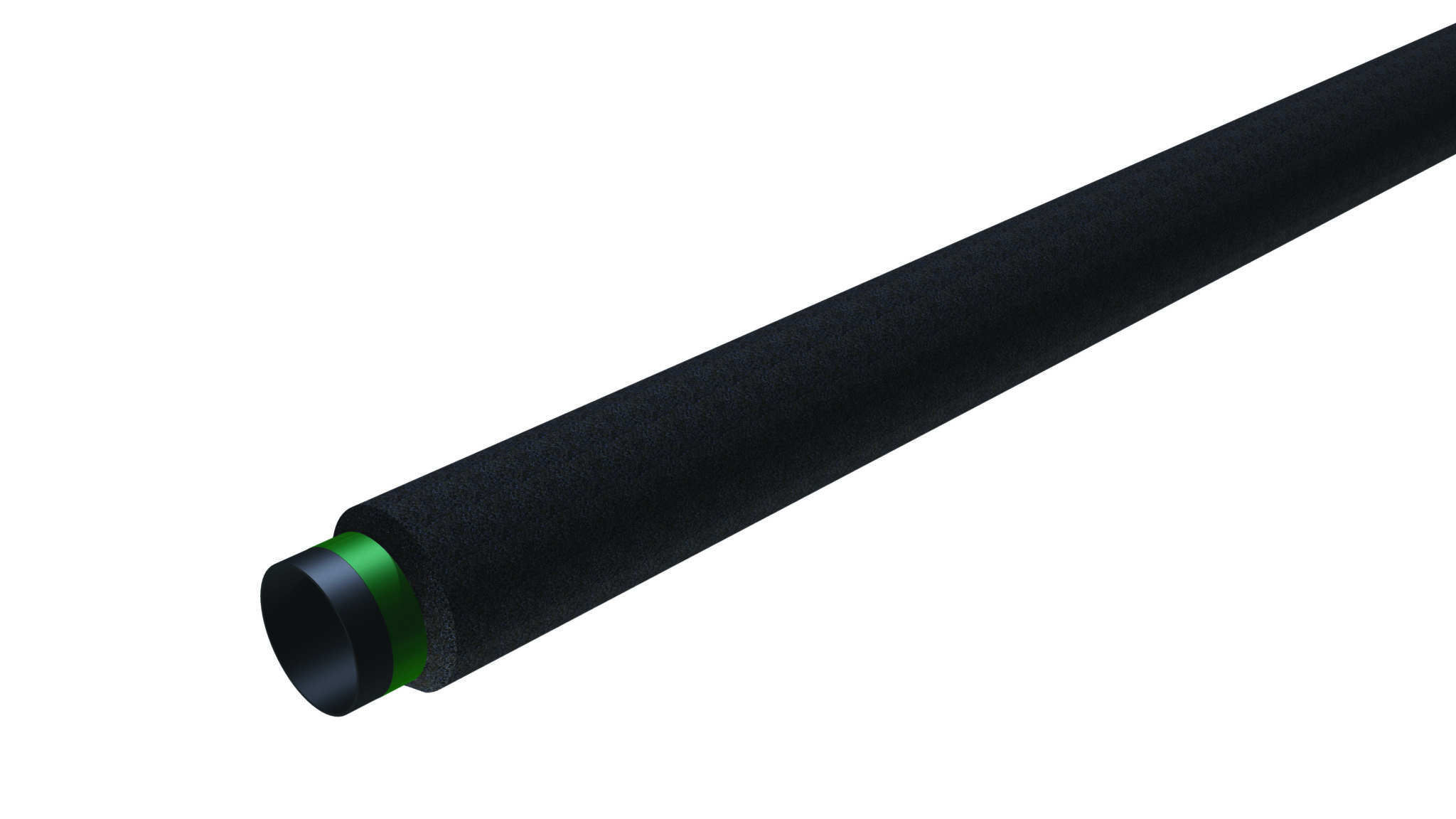

CONCRETE WEIGHT COATING

Concrete weight coating is a plant-applied coating used to achieve negative buoyancy. Bayou has coated over 4.5 million feet of pipe with concrete weight coating to date.

Application process

- Bayou uses a compression wrap process which keeps the anti-corrosion coating free of damage. Concrete is applied by wrapping a uniform layer while simultaneously wrapping reinforcing wire within the concrete coating for stability

- A calculated mixture of cement, sand, iron ore and wire wrap is applied to a predetermined thickness and density level

Coating Components

- The concrete weight coating system is typically used in conjunction with other coating systems such as FBE and 3LPP/E.

- Bayou uses various methods to avoid slippage between the concrete layer and anti-corrosion coating. These include adding a rough-coat layer or applying a 2-component epoxy adhesive to bond the concrete to the coated surface.

- Bayou offers integrated anode installation to maintain the integrity of the cathodic protection system.

portable plant capabilities

- Bayou has a containerized mobile CWC plant that offers CWC application in close proximity to the project site.

primary specifications

- 8 in. min to 48 in. max OD

- Pipe lengths: 35 ft. min to 45 ft. max

- Density range: 140#, 165#, 190#, 210#

applications

To achieve negative buoyancy for:

- Offshore pipelines

- Pipelines in wetland environments

- River / Road crossings

MEDIA & LITERATURE

Coming Soon