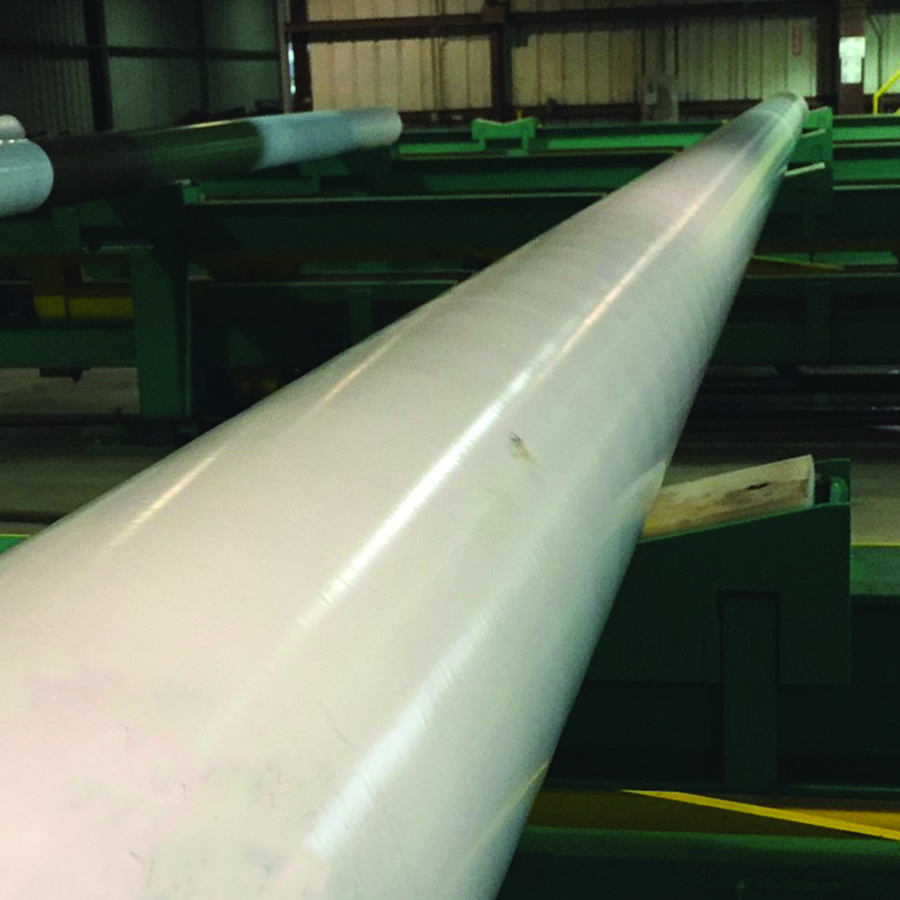

3-Layer Polyolefin

Our 3 layer coating products start with an FBE primer and a polymeric adhesive. Next, an outer jacket of HDPE or HDPP is added as the final layer, depending on project specific requirements.

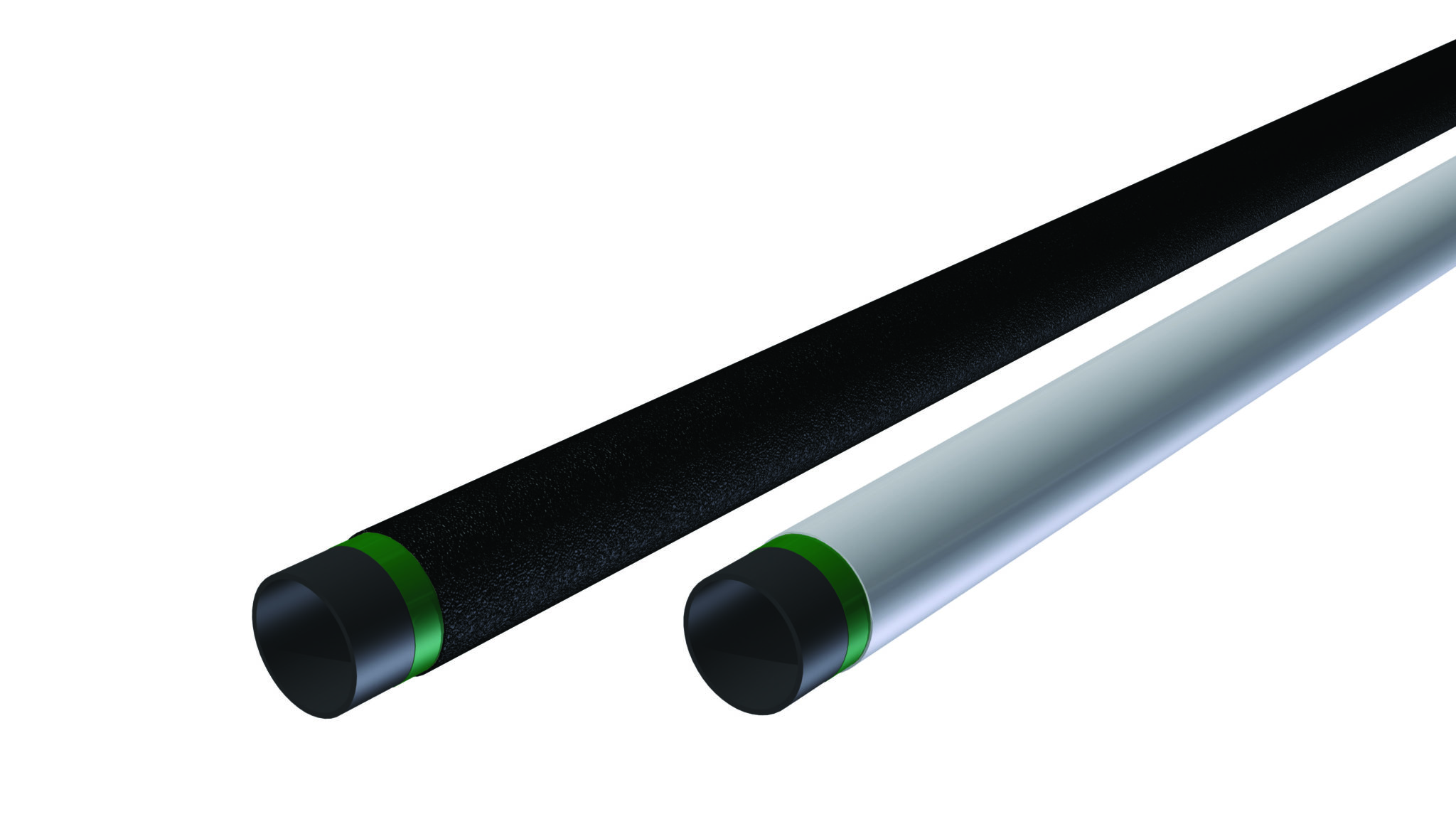

3-Layer Polyethylene (3LPE)

- FBE primer + polymeric adhesive + HDPE extruded jacket

- FBE thickness: 10 mils min

- Adhesive thickness: 8 mils min

- HDPE thickness: 40 mils min

- 6 in. min to 48 in. max OD

- Pipe lengths: 35 ft. min 80 ft. max

- Max operating temp: 85°C

- Min handling temp: -40°C

- Offers superior adhesion, cathodic disbondment resistance and mechanical protection

- Compliancy: CSA Z245.21-06 B1

3-Layer Polypropylene (3LPP)

- FBE primer + polymeric adhesive + HDPP extruded jacket

- FBE thickness: 10 mils min

- Adhesive thickness: 8 mils min

- HDPP thickness: 40 mils min

- 6 in. min to 48 in. max OD

- Pipe lengths: 35 ft. min 80 ft. max

- Max operating temp: 150°C

- Min handling temp: -40°C

- Offers superior adhesion, cathodic disbondment resistance and mechanical protection

- Compliancy: CSA Z245.21-06 B1

applications

- Used in rugged / moderately rocky terrain

- Ideally suited for directional or bored crossings

- Exceptional for moist conditions

MEDIA & LITERATURE

Coming Soon